Handmade wedding rings made with a lathe

I am Shindo, a craftsman at MITUBACI. Today, I would like to introduce a lathe in the MITUBACI workshop.

MITUBACI has added a new option for handmade wedding rings: "lathing".

Let me tell you what kind of machine a lathe is, what it can do, and who is suited for it.

What is a Lathe?

A lathe is a machine that fixes and rotates the metal to be cut and presses a steel or diamond blade against it to cut it..

We can precisely process various machine parts and screws.

In the case of rings, they can be shaved into various shapes.

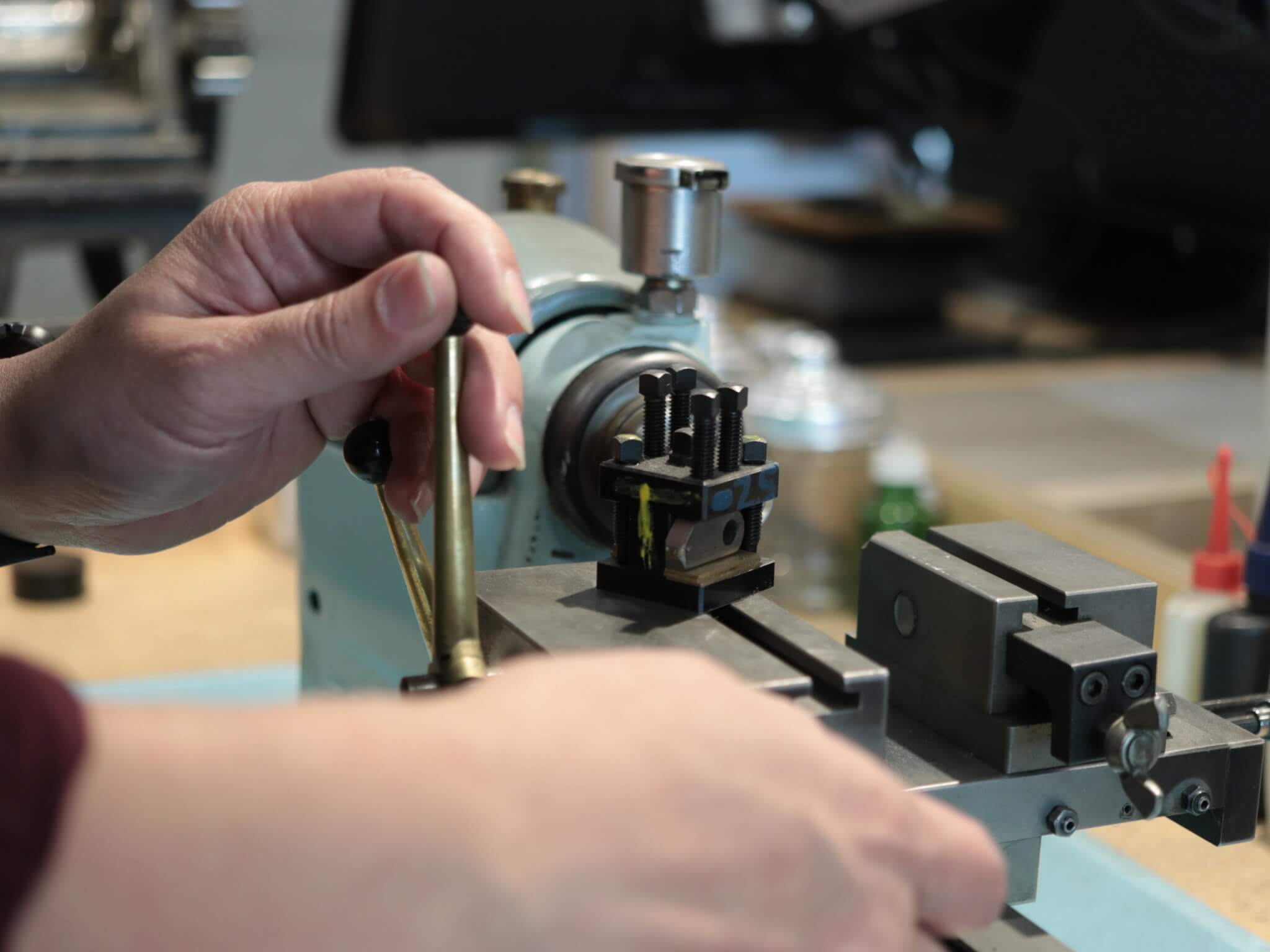

A lathe usually grips the metal to be fixed from the outside, but in the case of rings, the rings are fixed to a stand called a chuck. The chuck is a brass instrument, available in different sizes for different rings. After the ring is placed on the chuck, the chuck is placed on the lathe, and the ring is fixed to the lathe as if it were being spread from the inside. This is called an "open yatoi," which is a slightly special way of securing the chuck.

After confirming that it is securely fastened, the foot switch is pressed and the motor rotates, spinning the shaft at high speed through the belt.

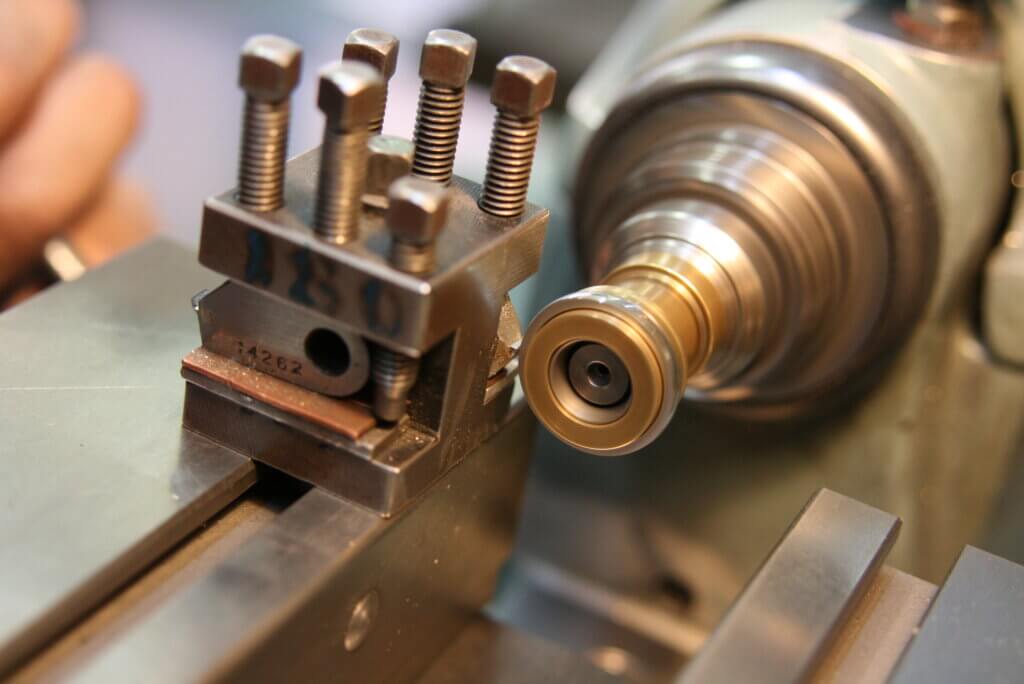

A fixed cutting tool called a bite is pressed against the rotating ring to cut the surface uniformly.

Lathe turning is characterized by its ability to produce a uniform shape all the way around, which cannot be achieved by hand work.

Precision required to use a lathe

Difficulty in using both hand work and lathes

MITUBACI performs lathe processing in conjunction with forging, but most of the base ring production is done by hand. While lathe turning can produce accurate rings, the original rings must be highly accurate to be securely fixed, and precision machining is not possible.

The accuracy of the ring required to use the lathe is the minimum error in any measurement of the width of the ring.5/100mm or lessThe first step should be to

To give you an idea of how accurate 5/100 mm is, the thickness of a sheet of copy paper that you often use is roughly 7/100 mm, so it is smaller than that. An error of one sheet of paper thickness is a large error for a lathe.

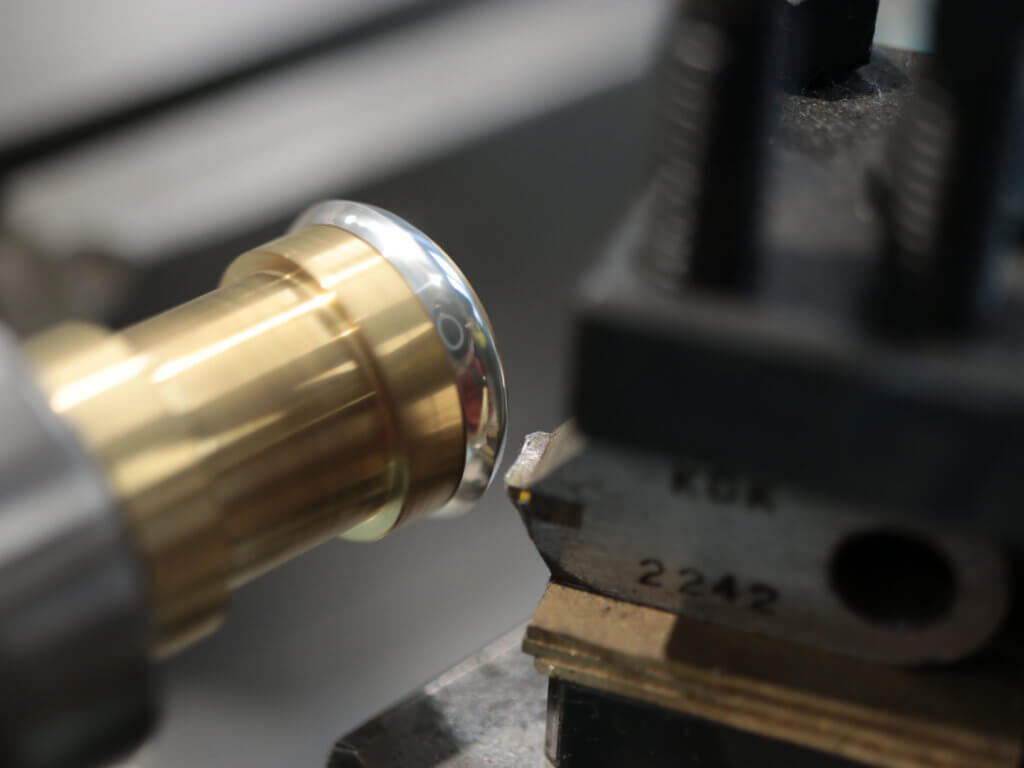

Difficulty of milling process

Lathe turning requires precision, especially when milling. When milling a ring, a groove is first made in the area to be milled. If there is an error in the thickness of the ring, a groove of uniform width will not be created, and the milling will not go in cleanly.

The difficulty of lathing is that the precision of the machine does not allow for even the slightest dimensional error, and this is what makes the finished ring so valuable.

Luxurious use of metal, lathing of rings

When lathe turning is used to make rings, more metal is required than the finished ring metal.

Since the base ring needs to be prepared thicker than the finished shape and dimensions, a lot of metal needs to be prepared.

In the casting process, on the other hand, a prototype is molded, a plaster mold is made, and molten metal is poured into the mold.

It is easier to understand if you think of it as a small casting.

A ring removed from plaster is almost ready to be shaped. The ring taken out of the plaster is polished, but it does not involve a lot of metal shaving as in lathe work.

Rings made using forging and turning are strong (forging process) and luxurious (turning process).

Introduction of lathes in MITUBACI's workshop

The lathe in MITUBACI's workshop is a 1972 Eguro PH6L-4H precision high-speed tabletop lathe.

Eguro is now a company called EGURO Corporation, so you can feel the age of the company when it is written "Eguro" in Chinese characters.

In MITUBACI's workshop, a workbench was created to match this lathe. It is painted light blue and has a strong presence.

There are computerized lathes, but this latheManual operation of everything.

The excellence of this lathe is twofold.

One is that the unit is compact and easy to handle.

The other is that cutting can be done while looking at the ring.

Being able to see the ring as it is being cut allows the craftsman to fine-tune the cutting as he wishes, allowing for more detailed work.

The way it is sharpened also depends on the metal to be cut. Therefore, experience is required to adjust the amount of blade pressure while watching the cutting conditions with a loupe.

About the bites (cutting tools) used at MITUBACI

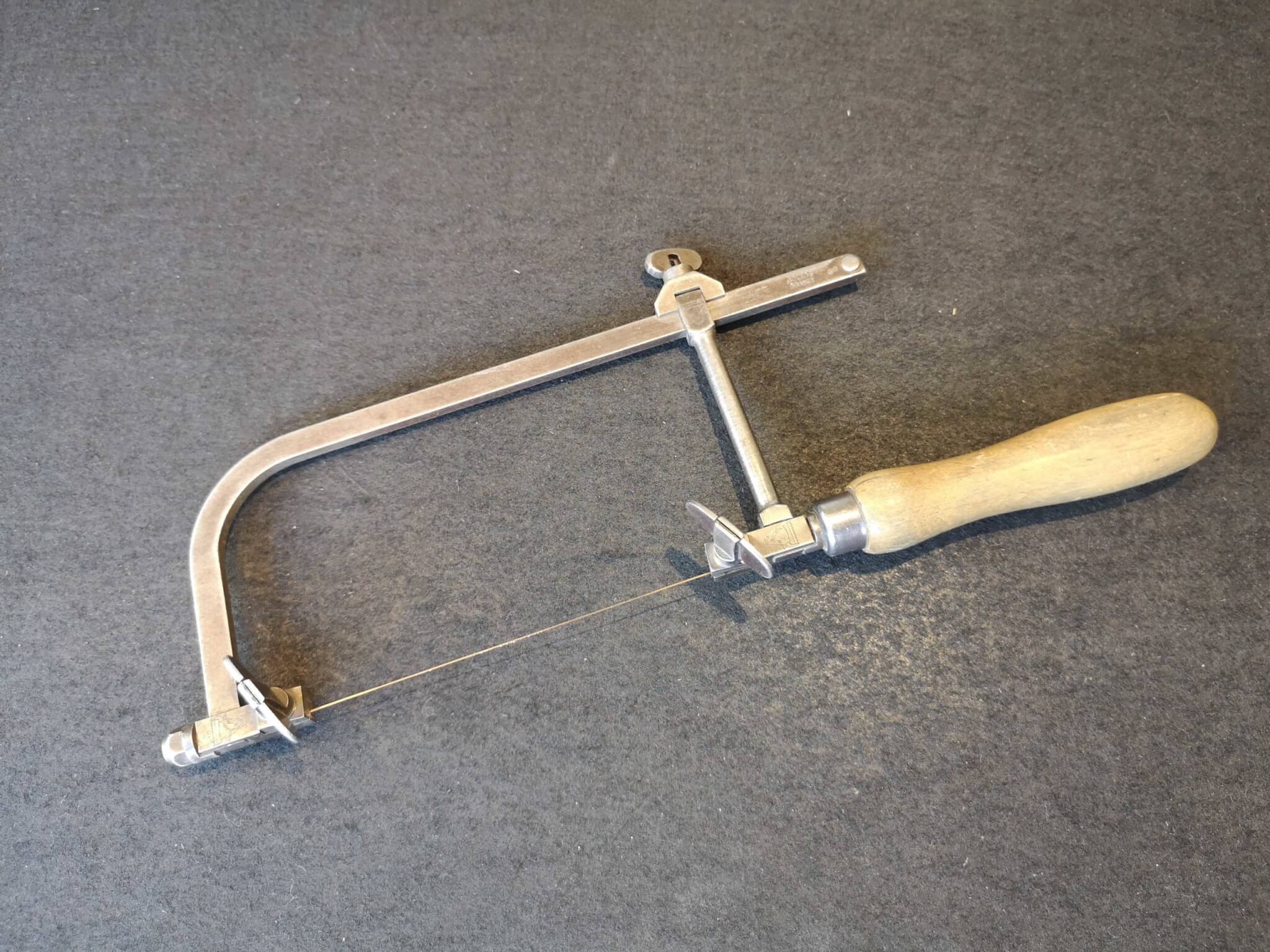

There are two types of bites (cutting tools) used at MITUBACI.

1. diamond blade

2. compax blade

Compax, a sintered diamond, is a material made by processing diamonds and is more impact-resistant than diamonds.

Both types of blades are very expensive, but the hardness of the blades makes it possible to cut gold and platinum firmly.

Although it takes skill to use a lathe with precision, a lathe can be used to process and groove the surface of a ring into a round shape with the same thickness all the way around the ring in a short time. A wide range of wedding ring designs can be created more quickly and precisely than when processing rings by hand using a file or other tools.

The lathe is also used in the production of custom-made wedding rings.

Lathing of handmade wedding rings is recommended for

Who is recommended to lathe handmade wedding rings?

1. those who want to do the engraving themselves, but want the ring to be as high quality as a store's product.

2. those who are not confident in using a hammer to cleanly process the work by themselves

3. those who like milling and other designs that can only be achieved by lathe turning.

4. for those who would like to take a closer look at the process of completing their own rings, rather than making them.

*If you choose the lathe machining option, theIn the latter half of the production process, the craftsman increases the number of processes to be processed..

Whether you choose the lathe machining option or not, please take a look at the "lathe" machine when you visit the MITUBACI workshop.

The handmade wedding ring designs that can be made with lathe work are here.You can read more about it at