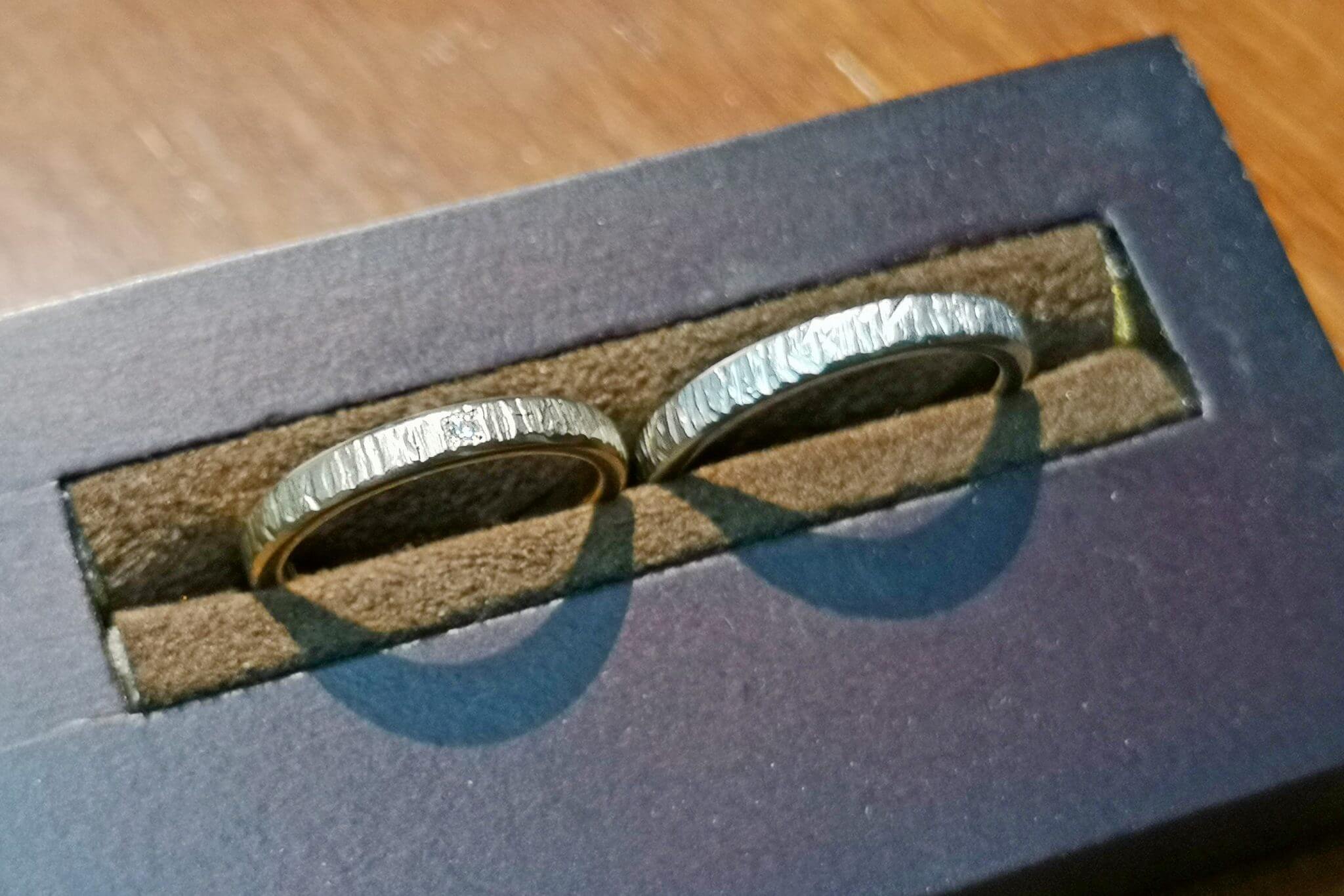

Ring details:

Left: 2.0mm width platinum950 with half matte hammered texture

Right: 1.7mm width platinum950 with hammered texture and diamond

Introducing K-san's brilliant diamond set platinum ring, and their half matte hammered texture wedding bands.

The lovely pair had opted to go for laser engraving for their wedding band. As such, there was no engraving practice before they started making their bands.

They carefully measured their ring size before our craftsmen prepared the materials. Once the preparations were done, the couple quickly begun the shaping process.

Using the ring bender tool makes the shaping process a lot easier for beginners and for those who have difficulty shaping the rings.

The next step would be to close up the gap in the ring. This is done through a process called soldering.

As platinum has a high melting point, an oxygen burner is required for the soldering process.

The use of such burners require a license so our artisans will handle the process for you.

With that, the ring is slowly starting to take shape. Next would be the polishing process.

The hammered texture is added after the ring has been polished.

The hammered texture is achieved by using a special hammer with a rounded tip.

Once the texture has been added, the ring is then sandblasted for a matte texture, and the diamond is then set.

Our veteran artisans will do this process for you as it requires skill. Lastly, the laser engraving is added.

Here is the completed ring!

The completed rings turned out very beautifully.

The ring on the right has a width of 1.7mm, making it perfect for layering as well.

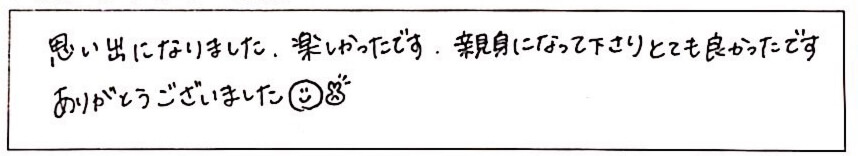

They kindly left a message for our staff as well.

"This was a memorable experience that we enjoyed. The staff was very accommodating as well."

"Thank you very much ^^"

***

Thank you for signing up for MITUBACI DIY workshop, K-san. We look forward to having you again at our atelier!

*This article is published with the consensus of the customers.