I am Fujimori, a craftsman at MITUBACI.

Today, I would like to introduce the gas burner for engraving used in our workshop.

What comes to mind when you hear the word "gas burner"?

I asked a customer who came to the workshop if it is used in restaurants for crème brûlée or fish. He answered, "Yes. I have seen gas burners sold at 100 yen stores. They are quite familiar to us.

The one shown here is for engraving, so the heat power is a little different.

When engraving, gas burners can be used for brazing (welding), annealing, and melting.

MITUBACI uses two types of burners.

The first type of gas burner mixes gas and air. Air is fed into the gas burner by a compressor.

By feeding air, the temperature of this gas burner rises to about 1300°C. The melting point of silver is 961.8°C and that of gold is 1064°C, so it is mainly used for processing gold and silver. Since the melting point of silver is 961.8°C and that of gold is 1064°C, it is mainly used for processing gold and silver.

The feature is that you can hold it with one hand and adjust the gas and air with just your thumb, allowing you to adjust the flame according to your needs.

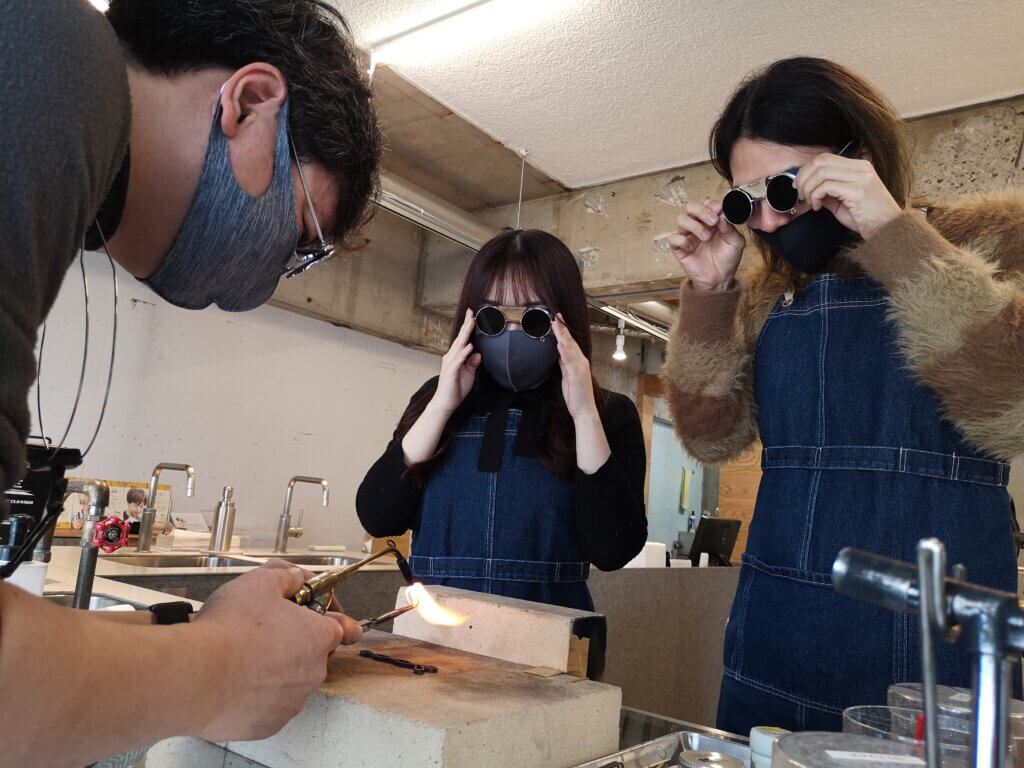

The brazing process for silver and gold rings can be experienced by our customers, and we encourage you to try it.

Next, we introduce the oxygen burner.

This type is used by mixing gas and oxygen. It is mainly used to process platinum.

The melting point of platinum is 1768°C, higher than that of gold or silver. For this reason, an oxygen burner is used, which mixes gas and oxygen to reach over 2,000°C.

When soldering platinum, use safety glasses to protect your eyes from glare due to the extremely high temperatures.

To use an oxygen burner, one must take a gas welding skills course and become qualified. Therefore, platinum brazing is done by MITUBACI craftsmen.

The brazing process for gold, silver, and platinum rings is one of the most exciting to watch and experience.

And if you'd really like to use the burner too! If so, please choose a gold workshop.