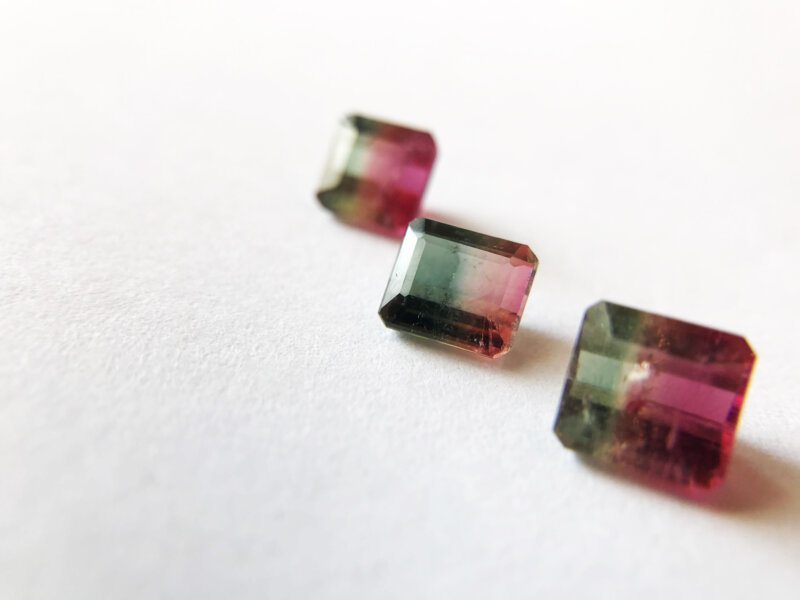

When purchasing a wedding ring, one often chooses a design, a brand, or material.

How about changing your perspective a bit and choosing a wedding ring based on the manufacturing methods?

Wedding Bands Manufacturing Methods

There are two main methods of manufacturing wedding rings: forging and casting.

Two Types of Wedding Ring Manufacturing Methods: Forging and Casting.

Although not widely known, there are two major methods of manufacturing wedding rings: forging and casting. Here, we will explain each of these manufacturing methods.

What Is Forging?

The forging process is a traditional manufacturing method that originated in Germany and has been around in Japan for centuries. It involves compressing a mass of metal, softening it by applying heat, and cutting, hammering, and stretching it repeatedly with a roller or hammer to form the ring. The forging process requires a great deal of time, skill, and experience. With that said, it is a time-consuming and costly process. Rings forged with this method are more durable and have a high degree of precision.

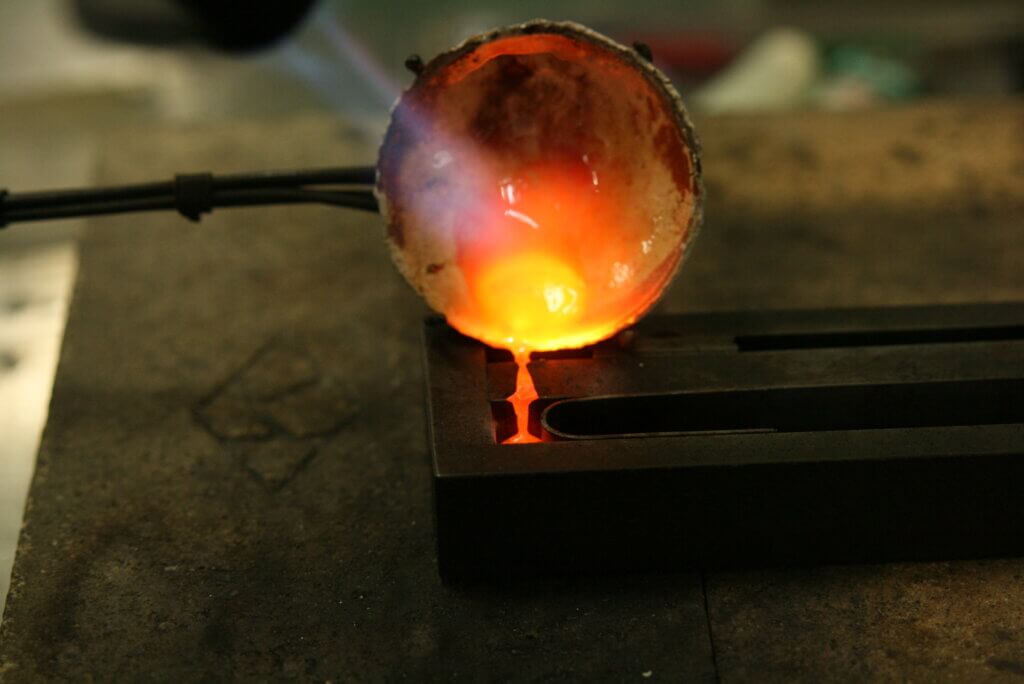

What Is Casting?

The wax casting method relies on pouring metal into a mold, a concept similar to making chocolates with mold. Before working on the actual ring, a resin prototype is created using a 3D printer. Next, the mold is created based on the form of the prototype. Once the mold is ready, precious metal is then heated, poured into the mold, and cooled to form the jewelry.

Pros and Cons of Forging Method

Advantage #1 Durable

The primary benefit of forging is strength. Forging is a process of forming metal by applying pressure or beating it into shape. When force is applied to the metal, unwanted air bubbles and gases are knocked out of the metal, the interior is crimped, and crystals are oriented. As a result, the metal becomes stronger.

Wedding rings made by the forging process have the great advantage of high density and hardness, and are resistant to pressure and deformation.

Advantage #2 A Comfortable Fit

The advantage of forged wedding rings is that they are comfortable to wear on the finger because the hard, forged surface can be polished carefully to enhance the brilliance and create a smooth surface finish. It is also characterized by its weight and the firmness of the metal's density.

Advantage 3_Everything is one-of-a-kind

Forging is a manufacturing method where each piece is made one by one, resulting in all pieces being one-of-a-kind. Since no prototype is required and each piece is formed from precious metal ingots, it is easy to change the width and thickness of the piece, allowing it to be arranged to your liking.

Disadvantages of Forging

The disadvantage of the forging process is that it is difficult to create complex shapes because of the process of forming and cutting by beating. Another demerit of the forging process is that it is not suitable for mass production, such as making many identical shapes at a lower cost, because no prototype is used.

Cast wedding rings, advantages and disadvantages

Advantages of Casting

Since the molding is done by pouring into a mold, complex designs can be accommodated. For example, arms can be designed with wavy or finely patterned designs. This high degree of freedom is a major advantage of the casting process. Another major advantage is that it is suited for mass production. With a single mold, several rings of the same design can be made simply by repeating the process of pouring, cooling, and hardening metal.

Disadvantages of casting

Casting is a process in which molten metal is poured into a mold. Since there is no process of forging the metal, the density is uneven and crystals are not oriented in the same way. In addition, air bubbles can easily enter the metal during the pouring process, creating small holes inside the metal, known as "su" in the technical terminology. As a result, the finished ring is less durable than forged rings, and it is difficult to finish with high precision, which is a disadvantage.

Manufacturers and brands in the world famous for forged wedding rings.

The casting method is used as a manufacturing method by manufacturers around the world because it allows for a variety of designs, is easy to mass produce, and is cost-effective. On the other hand, Germany and Switzerland have the largest number of manufacturers using the forging method. There are also manufacturers in Japan that use the forging method. We would like to introduce some of the traditional manufacturers in Germany, Switzerland, and Japan who have adopted the forging method, in the hope that they will be helpful in familiarizing you with the forging method.

FISCHER

FISCHER is a prestigious German workshop with a history of over 100 years. The rings produced by the fusion of the traditional skills of the meisters, which have been passed down from generation to generation, and cutting-edge technology are of high quality and have a unique charm that cannot be found anywhere else. The main feature of our rings is the careful handcrafting of the many steps involved, from forging to shaping and engraving. Our commitment to producing our own ingots allows us to develop products that meet the needs of customers in various parts of the world.

Furrer Jacot

Furrer Jacot is a long-established Swiss manufacturer that has been independently owned and operated for more than 160 years, since the founding of its jewelry store in 1858. The wedding rings produced by its highly skilled goldsmiths (goldsmiths) are of the highest quality.

Pilot

Pilot is a stationery manufacturer best known for its fountain pens and other products. Pilot also manufactures sophisticated and beautiful rings, utilizing the outstanding technology cultivated in fountain pen manufacturing, and operates a bridal brand called PilotBridal. The company manufactures rings in pure platinum (Pt999) in-house, which is not found anywhere else, and uses a technique called Uchikamaru to improve comfort, and the rings are characterized by attention to detail and dignity.

Who is recommended to have a forged wedding band?

As we have mentioned, wedding rings made by the forging process are highly durable, and their main feature is that they are more resistant to deformation and scratches than those made by casting. For this reason, they are recommended for people who want to wear them on their fingers all the time and not take them off when doing housework or raising children.

Also, forged wedding rings, which are made with a constant width and thickness due to the manufacturing process, are simple in shape. They are suitable for those who prefer a universal design that is not influenced by trends or age-related preferences, and that will never grow old.

Handcrafted forged wedding rings!

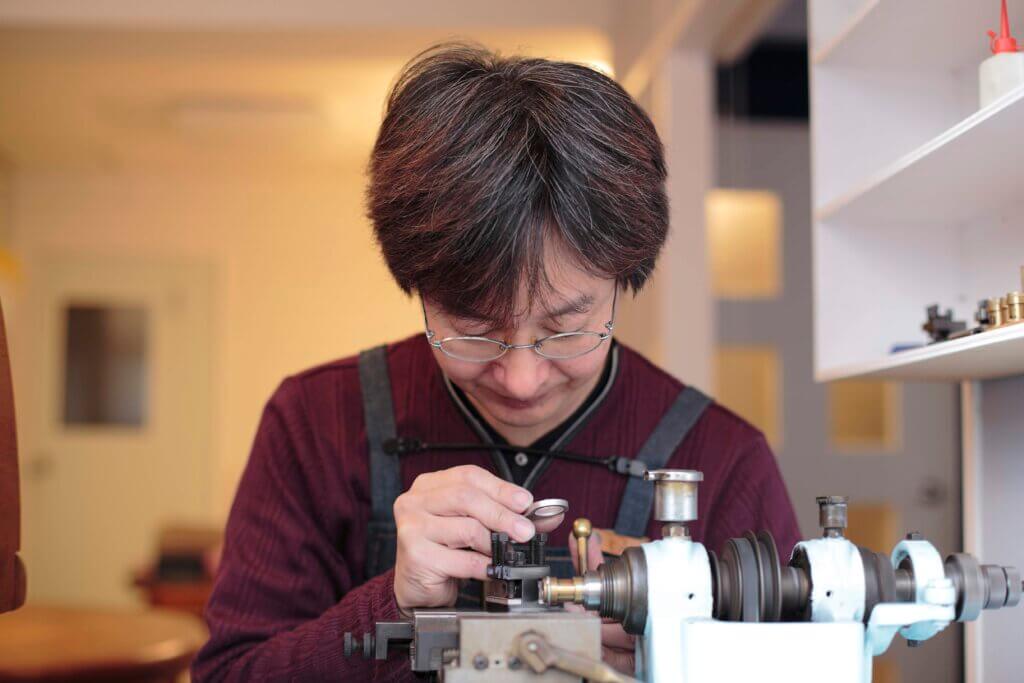

The forging method is a process in which craftsmen painstakingly create the product by hand.

This makes them ideal for customizing wedding rings or making them themselves.

However, even if we were to make it ourselves, we would not know how to do so without knowledge.

The main attraction of MITUBACI's handmade wedding ring workshops is that they allow you to create your own unique wedding rings with the assistance of experienced craftsmen.To be able to complete the wedding ring on the same day it is made and take it home with you.Of course, there are many people who just put the ring on their finger and go home. Of course, there are also many people who put the ring on their finger and go home with it, but because MITUBACI's handmade wedding rings are made by professional craftsmen, the finishing touches are done on the spot, and if there are any diamonds or other gemstones to be set, they can be done on the spot and taken home that same day. If you have any diamonds or other gemstones, we can handle them on the spot and you can take them home that day. (Please note that some time will be required to complete the work).

Another major advantage of MITUBACI's handmade wedding rings is that they can be made to fit your finger perfectly.

Unlike the casting method, which uses wax to create the original shape, the forging method uses a ring-shaped base metal, which is formed little by little as it is tried on the finger over and over again. This allows for fine adjustments.We can always make a ring in the exact right size.The first is the

Couples who are worried about whether they can make the rings on their own need not worry. Our skilled craftsmen, who have been making rings as specialists in the forging process for more than 50 years since the company's establishment, will carefully support the couple and manufacture their own rings using the same process that real craftsmen use. If they make a slight mistake, the craftsmen will recover. There is no such thing as "it's handmade, so it's not good enough." Our professional craftsmen will help you make a beautiful wedding ring with pride.

Get a ring that you both agree on! Why not consider making it by hand?

The forging process is a process in which metal is beaten and forged to carefully form a shape.

Two people who are particular about forging can also choose a manufacturer or brand to purchase, but why not try handcrafting with MITUBACI using the forging method?

The time and experience of making a ring at MITUBACI has a special meaning for the couple, and the finished ring is something they will love even before they wear it.