Finding a wedding ring is one of the most enjoyable preparations for a wedding. While wedding rings of various designs are sold, wedding rings can actually be handmade. In this article, we will show you how to make rings at a store that offers "handmade wedding rings.

How to make a handmade ring

Offers information on how wedding and engagement rings are made. Rings are made in two main ways: casting and forging.

We will tell you how to make each one in detail.

How to make wedding rings

What is the forging process?

The forging process, as the name suggests, is a process of forging metal by beating or applying fire to it to create a shape. For an easy-to-understand description of "forging metal," it is easy to understand if you imagine the scene you have seen in movies and animations, where swords are heated and beaten with a hammer to finish them off. In Japan, this method is believed to have been used since the Yayoi period when iron began to be processed. Today, forged parts are used for car wheels, which are required to be strong, and for parts of rockets that travel into space.

How a forged ring is made

The forging process is not often associated with rings, but rings made by forging are flexible, comfortable to wear, and of course strong, so it is actually a recommended process for wedding rings that are supposed to be worn for a long time. Here we introduce the process of making forged rings.

1. Prepare materials by applying heat to metal

First, the material metal is heated and then beaten with a hammer or stretched with a machine called a roller to increase its density and strength as a material. The most common metals used for wedding rings are K18 gold and Pt950 platinum. The forged material is then shaped into a plate. Usually, most stores that offer handmade wedding rings prepare the work up to this point before the customer arrives at the store.

2. Cut out the material metal

The metal prepared in sheet form is prepared according to the width and size of the ring to be completed.

Prepare the ring a little wider than the planned finished width in anticipation of shaving and polishing. Also, the length will depend on the size of the ring. If it is a smaller size, it will be shorter; if it is a larger size, it will be longer. In the case of hammered rings, which are finished by striking the surface with a hammer, the length should be prepared slightly shorter than both the length and the planned size, since the size will increase as the ring is struck.

It is difficult for an amateur to judge the "slightly" larger or "slightly" shorter width or size, so in the case of handmade wedding rings, we leave it to the craftsmen and store staff who will work with you.

3. Shape the ring

A sheet of metal prepared to fit the finished ring is shaped into a ring.

Some workshops make round, perfect circle shapes from the start, while other stores make shapes that can be welded (ovals, triangles, etc.) for now.

4. Welding

The ends of the plate material are welded together. This process is called brazing. The metal pieces, called brazing filler, are used to connect the two pieces together. The brazing material is a piece of metal that is the same metal as the body of the ring, but is formulated with a lower melting point (melting temperature) than the body. The wax is heated and melted to form the joints. If the shape of the ring was oval or triangular when it was made, it is brazed and then shaped into a round ring.

5. Shape and size the ring.

The metal in the shape of a ring is struck with a hammer to shape and size it. If a hammered pattern is to be applied, the entire ring is struck around and around with a special hammer at this time to add texture. The ring is worked through a core bar with knurls for each size.

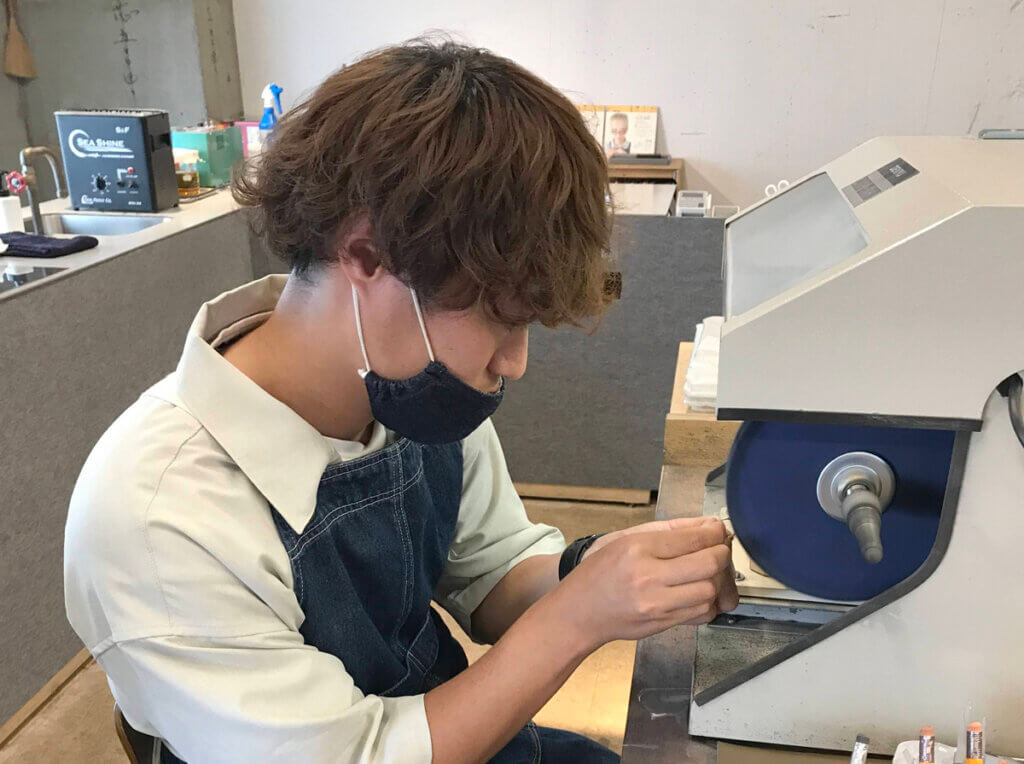

6. Polish and finish the ring.

After the ring has been shaped and sized, it is polished and finished. Sandpaper is used for finishing. The sandpaper is gradually made finer and finer, starting from the coarsest sandpaper. The sandpaper may be in the form of paper itself, wrapped around a stick, or polished using a rheuter. The tools used vary from workshop to workshop and store to store. After polishing with sandpaper, the piece is polished with a special polishing machine called a buff. This process may be done by the customer or by the store.

7. Completion

After polishing, it is cleaned and finished. If a diamond or other gemstone is to be fastened, this is done after this process. After clasping the gemstone, polish the jewel lightly. Ishidome" is the process of fastening gemstones, which requires special tools and skill, so it is done at the store. At stores that have jewelers who can do this work, you can receive your jewelry on the same day.

MITUBACI uses the forging method to make handmade wedding rings.You can see it here..

Forged wedding rings other than handmade wedding rings

In addition to the production methods introduced above, the forging process also involves pressing the metal in a special machine and then punching or cutting the compressed mass into a round ring shape. This forging technique originated in Germany, but as a handmade wedding band, it is a bit more difficult for a non-craftsman to make.

You can read more about the forging process in this blog, if you would like to know more.

How to make wedding rings|Casting method

What is the casting process?

Casting is the process of pouring molten metal into a mold to create a shape. The process is similar to pouring melted chocolate into a mold and letting it harden. The same shape can be made many times as long as the mold is not broken. In addition to metal, plastic and rubber products can also be made using the casting process.

How a casting ring is made

Handmade wedding rings made by the casting process can be very finely crafted. Here we introduce the process of making handmade wedding rings by casting.

1. Making the prototype 1_Materials for the prototype

The process of making a wedding ring by casting begins with the creation of the original mold, called a prototype. The mold is made from a soft, candle-like material called wax. There are several types of wax, but most handmade wedding ring stores use tube wax, which is round in shape from the start. Wax comes in a variety of colors, including blue, green, and purple. Each has a different melting temperature and softness and suppleness.

2. Create the prototype 2_Form the shape

The tube wax is shaped like a long stick, so it is cut out to fit the width of the finished ring. There are two types of rings: one with holes where the finger enters from the beginning, and one without holes. In both cases, the hole is widened or drilled to fit your ring size. Next to the width, the thickness is adjusted. The thickness is determined by cutting it out with a thread saw or by filing. The desired design shape is created by shaving with a spatula or by adding a pattern.

In the case of handmade wedding rings, the part we work on ourselves is usually the making of the prototype.

3. Make molds

A mold is made from a prototype made in the shape of a ring. The prototype is covered with a material that can withstand fire, such as silicon rubber. When the ring is put on fire, the wax in the prototype cannot withstand the high temperature and melts away, creating a cavity inside the rubber in the shape of the prototype. This creates a cavity inside the rubber in the shape of the prototype, which becomes the mold. This process is also called the lost wax process because of the way the mold is made.

Casting operation_Metal is poured into a mold

The molten metal is poured into the mold and allowed to cool and harden. This is a difficult process because if the temperature of the metal is too high or too low, the product will not be beautiful.

5. Polish and finish the ring.

The finished ring may be rough as it is, and depending on the casting process, there may be protrusions or overhangs called "burrs" that were not on the original mold. These are polished and finished. If there is a matte finish, it is also polished before processing.

6. Completion

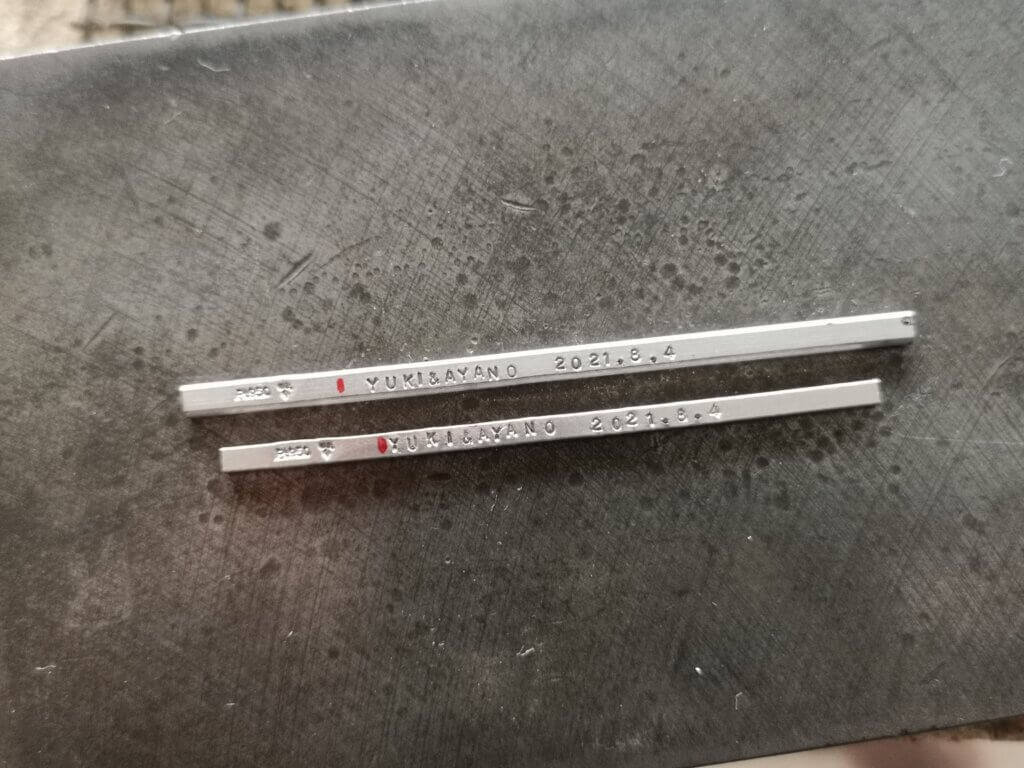

Once the ring is polished and cleaned, it is finished. Laser lettering and gemstone clasps are done after polishing. Laser engraving and gemstone clasping also cause scratches and burrs, so they are also polished after the work is done.

In the case of handmade wedding rings made by casting, there is usually a delivery time of about one month because of the work involved by the craftsman after the prototype is made.

MITUBACI's handmade wedding rings are forged.

How to make MITUBACI wedding rings using the forging process

MITUBACI's handmade wedding rings are forged.

For more information on how to make MITUBACI handmade wedding rings, see<Production FlowIntroduced in an easy-to-understand manner in.

FAQ

FAQ

Reliable Strength

Q: We made the rings ourselves, and we are worried that they will break.

A: Even if the rings are handmade, there is no need to worry, as our craftsmen will follow up with you to ensure that they are produced properly. all of the craftsmen who conduct MITUBACI workshops are professionals who have been making wedding rings for many years, so you can work on your ring with confidence.

Warranty

Q: I am concerned about the proper warranty.

A:MITUBACI wedding rings are guaranteed for many years. Wedding rings are meant to be used for a long time. We want you to be able to use it comfortably for a long time, so please feel free to contact us no matter how many years have passed since it was made.

Q: What is cleaning?

A: For cleaning, rings are cleaned with an ultrasonic cleaner. We can clean the hard-to-reach areas. If desired, we can lightly polish the ring using a machine called a buff. We cannot remove deep scratches, but fine scratches will be cleaned. We are often consulted when there is time between the purchase of the ring and the wedding or photo shoot and the ring has been used on a daily basis.

Q: What is a new finish?

This is the process of using a laser or other machine to clean out deep scratches that cannot be removed by cleaning. It takes about 2 weeks after we receive the ring.

Q:Please tell me about resizing.

A: We offer free re-sizing for the first time. There is no charge, but since finger size varies from one to two sizes depending on the season and your physical condition, we ask that you give it a try even if it is a little tight or a little loose. Summer is better than winter.

Delivery on the day

Q: I want my wedding ring this weekend, and I don't want to compromise on materials, letter engraving, gemstones, etc. Can you make wedding rings with letters and diamonds even if I take them home on the same day?

A:At MITUBACI, you can take it home on the same day. This is also a good option for customers who are in a hurry and plan to use the product in the near future.

If there are no options, the ring can be delivered in 2.5 to 3 hours. However, if there are options such as diamonds, it will take more time for our craftsmen to complete the work, so we ask that you please allow plenty of time for your visit. Also, you can save time if you visit our store after reviewing the design and ring material on our website in advance. If you have any questions in advance, please feel free to contact us using the inquiry form.

About materials and design

The wedding rings that can be made at MITUBACI are Pt950 platinum and four types of K18 colored gold.

As for the type.This page for wedding ringsPlease refer to the following page. You can try on samples of both items on the day of the event and make your decision while viewing them.

If you are concerned about the metal content of each or your allergies, please contact us.This column, "[Worried about metal allergies] How to find a wedding ring and whether or not you can make a handmade wedding ring".Please check the information on the following page.

Other Frequently Asked Questions

For other frequently asked questions, please contact<Please refer to the FAQto the

Please feel free to contact us with individual questions using the inquiry form.